Robotic Case Packer

Product Details:

- Type Robotic Case Packer

- Material Stainless steel

- Automatic Grade Automatic

- Drive Type Electric

- Click to View more

Robotic Case Packer Price And Quantity

- 1 Unit

Robotic Case Packer Product Specifications

- Stainless steel

- Automatic

- Robotic Case Packer

- Electric

Robotic Case Packer Trade Information

- 10 Days

Product Description

iRobolution delivers Robotic Case Packer for complete box filling and packaging of goods by with and without robot. Robotizing production/manufacturing lines will not only be fast and efficient system but a blazing piece of technology which is modular directly proportional to the space.

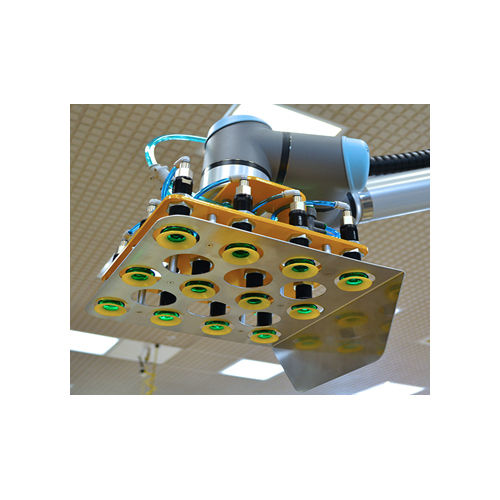

Robots can pick single or multiple items to pack single or multiple cases per cycle. Easy change end of arm tooling can prepare the same robot to handle products of varying sizes or shapes.

iRobolution designs robotic case packers that enable manufacturers to reduce labor and safety costs while increasing throughput, reliability, and accuracy of orders.

Robotic Case Packer Works

Products are automatically transferred into the robotic cell and are queued for packing. Packages are erected and fed into position where the system will initiate the packing process. Using a custom EoAT, the product is then picked and placed by the robot to the desired package. Once the packaging is complete it will exit the system and the robot will continue the packing process. iNovatRCP is enabled of handling multiple SKUs on the same line. According to the clients requirements iNovatRCP can cater more than one line of cartons/cases and goods considering the achievable cycle time.

Value addition:

- Eliminating the maximum error and gives much more reliability

- Repeatability

- Compact design & robotic flexibility in terms of layout and programming

- Low Maintenance

- No breakage and product damage or marking on the product

- Accurate packing numbers

- Touch panel for operation, error reporting, diagnostics etc.

- Remote support module for worldwide support

- Industry 4.0 enabled, IIOT enabled

- Robot system for case packing of products

- Custom-built robot gripper (Easy and flexible gripper designed to handle different profile of products), iGrip features

- Unique Hopper assembly to ensure easy handling of carton flaps open position and no product foul during packing

- Ready to integrate in-feed conveyor

- Unique Matrix arrangement design based on product shape, size and formation

- System guarding with Safety interlock doors as per safety norms. (CE/UL/CSA)

- Top & Bottom tapping machine (optional)

- Touch screen (HMI) control system with IOT enables and future configurable system

- Unique Recipe function for running different SKUs on the same line

- Ethernet connectivity for remote support

Application:

iNovatRCP can be used for multiple case packer applications like bottle packing, mono box to shipper box packing, plastic packets, pouch, JAR, Cans, etc in FMCG, food and pharma packaging industry Bottles| JAR| Cans |Mono Box| Pouch |Packets| Leaflet| Packet Strings

Line Speed up to 200BPM

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese