iR dpaDrum

Product Details:

- Product Type iR dpaDrum

- Automatic Grade Automatic

- Drive Type Electric

- Click to View more

X

iR dpaDrum Price And Quantity

- 1 Piece

iR dpaDrum Product Specifications

- iR dpaDrum

- Automatic

- Electric

iR dpaDrum Trade Information

- 10-15 Days

Product Description

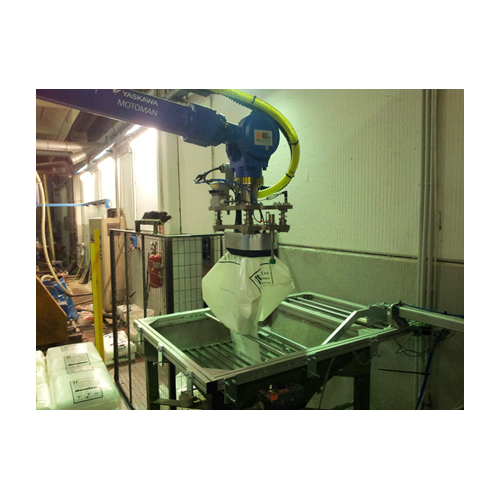

Robotic de-palletizer (iR-dPa) is a system which is capable of handling the most vital fragment of start of the line. iR-dPa is a fully integrated robotic system which has a flexible design, robust build, and easy installation. This well-designed technology can handle multiple lines in manufacturing/production area. Adding i-Vision gives unique features of ViPoCo Technology which can detect the orientation of bung location to feed in filling line without any mechanical arrangements.

Technical Specification for Robotic Bag Palletizer Automation

- Type: 1 in / 1 out, 2 in / 2 out, 3 in / 3 out or customize.

- Payload Capacity: 10Kg, 25Kg & 50Kg

- Palletizing Speed: 8-10 Bags / Min.

- Reach: Up to 3 meters

- Accuracy: -/+ 0.1 mm

- Power Supply: 380-480V, 50/60 Hz

- Control System: PLC or PC-based with HMI interface

- Safety Features: Safety fencing, emergency stops, light curtains

- End of Arm Tooling (EOAT): Customizable grippers for different bag types

- Integration Capability: Compatible with various conveyor systems and warehouse management software

- Environmental Conditions: Operating temperature range from -10deg C to 45 deg C

- Footprint: Customizable based on the layout

13. Solution: Pallet on conveyor or pallet on ground.

Features of Robotic Bag Palletizer Automation

- High Flexibility: Can handle different bag sizes, weights, and materials.

- Precision Handling: Ensures accurate placement of bags on pallets.

- User-Friendly Interface: Easy programming and operation through an intuitive HMI.

- Multi-Pick Functionality: Capable of picking multiple bags at once to increase efficiency.

- Adaptable Grippers: EOAT can be easily changed to accommodate different bag types.

- Real-Time Monitoring: Equipped with sensors and cameras for real-time process monitoring.

- Energy Efficient: Optimized power consumption with energy-saving modes.

- Safety First: Advanced safety systems to protect operators and equipment.

- Seamless Integration: Easily integrates with existing production lines and warehouse management systems.

- Robust Construction: Built to withstand harsh industrial environments.

Benefits of Robotic Bag Palletizer Automation

- Increased Productivity: Significantly higher palletizing speeds compared to manual handling.

- Improved Accuracy: Consistent and precise stacking reduces product damage.

- Labor Savings: Reduces the need for manual labor, lowering operational costs.

- Enhanced Safety: Minimizes human interaction with heavy loads, reducing injury risk.

- Scalability: Easily scalable to meet growing production demands.

- Reduced Downtime: Reliable operation with minimal maintenance requirements.

- Cost Efficiency: Long-term cost savings due to increased efficiency and reduced labor costs.

- Versatility: Can handle various bag types and palletizing patterns.

- Sustainability: Energy-efficient operation contributes to a lower carbon footprint.

- Future-Proof: Easily upgradable with new technologies and software updates.

Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese